Do you have questions?

PipePatrol Line Break Detection

Pipeline Management Solutions

Pipeline ruptures can result in dramatic consequences, endangering public safety and the environment. It is critical that fast acting rupture detection, response systems and procedures are designed, structured, and executed effectively. This is especially true for high consequence areas (HCA), where populated areas, ecological resources or water sources are in danger. To minimize the environmental effect the line break detection systems have to be reliable and fast acting.

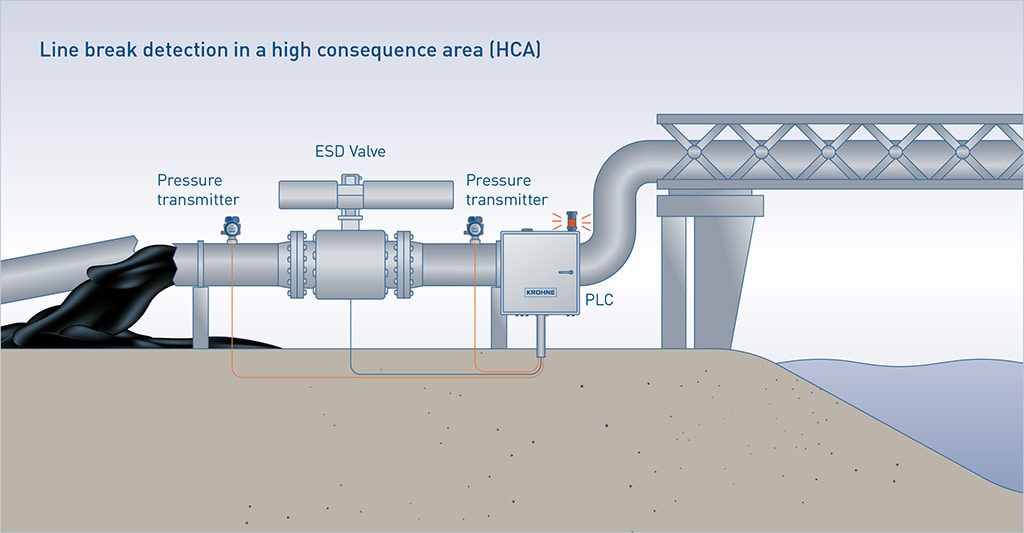

PipePatrol Line Break Detection is a dedicated system to efficiently detect pipeline ruptures instantly, raise an alarm and initiate emergency pipeline shutdown procedures. The system consists of a local PLC with Rupture Pattern Recognition installed, plus two pressure transmitters to act as the pipeline rupture detection sensors. The PipePatrol system includes a self-learning feature for easy commissioning and tuning to the local pipeline operational conditions. Configuration can be done via a local display, or remotely. Complying with API 1175 & API – Association of Oil Pipelines (AOPL) Liquid Pipeline Rupture Recognition and Response.

Line break detection in a high consequence area (HCA)

Line break detection in a high consequence area (HCA)

Highlights:

Pipeline Rupture Pattern Recognition system for automatic emergency shutdown

Self-learning feature eases commissioning work on site

Can be autonomous or integrated into a complete leak detection system

Configuration via local display or by remote access

Fail-safe system version available

Learn more about PipePatrol Line Break Detection in this video